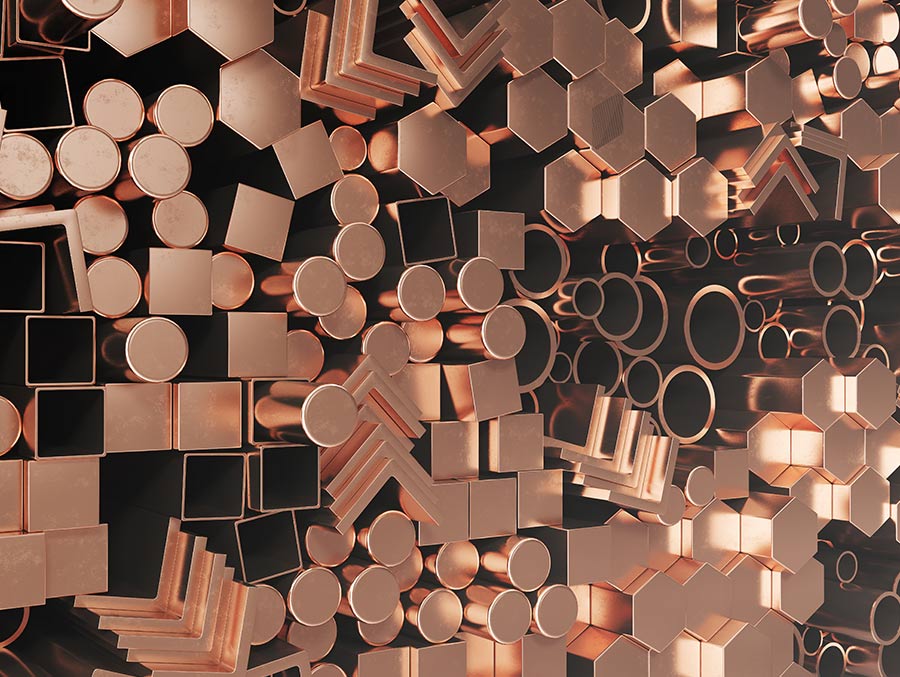

BRASS FLAT BARS AND RODS

Due to their physical characteristics and the ratio of copper to zinc within the alloy, brass rods are usually used in the metal processing industry, sanitary equipment industry and for construction of water and heat supply installations. Brass rods are also used for construction of electro materials, in the machine processing industry as well.

Brass flat bars and rods with lead-free

| Temper Designation | Product | Dimensions in mm |

| CuZn10

CuZn20 CuZn28 CuZn30 CuZn33 CuZn37 CuZn40 |

Round rods | dimensions: 3 – 80 |

| Square rods | diameter: 4 – 50 | |

| Hexagonal rods | dimensions: 4 – 60 | |

| Flat bars | width 4 – 12

thickness 8 – 18 |

Brass flat bars and rods – leaded

| Temper Designation | Product | Dimensions in mm |

| CuZn36Pb3

CuZn38Pb2 CuZn39Pb2 CuZn39Pb3 CuZn40Pb2 |

Round rods | 3 – 90 |

| Square rods | 4 – 60 | |

| Hexagonal rods | 4 – 60 | |

| Hollow rod (round and hexagonal) | according to customer demand | |

| Flat bars | width 4 – 12

thickness 8 – 18 |

FORM OF DELIVERY: Basic factory dimensions vary from 2 to 4 meters. Round rods of up to 18 mm diameter and hexagonal rods of 16 mm diameter (up to the opening of the wrench) can be delivered in coils.

APPLICATION: Due to their physical characteristics and ratio of copper to zinc within the alloy, brass rods and profiles can have a wide range of application. These rods and profiles are usually used in the metal and machine processing industry. Because hardness of brass is much higher than that of copper, brass is generally used for different types of valves, for production of sanitary equipment and for construction of water and heat supply installations. Due to their high electrical and thermal conductivity, brass rods are also used for production of electronic materials, in the machine processing industry as well as for decorative purposes in architecture.

Quality

| EN | EN for products | DIN | ASMT | |

| by letters | by numbers | |||

| CuZn10 | CW501L | EN12163 | CuZn10 | C 22 000 |

| CuZn20 | CW503L | EN12163 | CuZn20 | C 24 000 |

| CuZn28 | CW504L | EN12163 | CuZn28 | |

| CuZn30 | CW505L | EN12163 | CuZn30 | C 26 000 |

| CuZn33 | CW506L | EN12163 | CuZn33 | C 26 800 |

| CuZn36 | CW507L | EN12163

EN12167 |

CuZn36 | C 27 000 |

| CuZn37 | CW508L | EN12163

EN12165 EN12167 |

CuZn37 | C 27 000 |

| CuZn40 | CW509L | EN12163

EN12165 EN12167 |

CuZn40 | C 28 000 |

| CuZn36Pb3 | CW603N | EN12164

EN12167 |

CuZn36Pb3 | C 36 000 |

| CuZn38Pb2 | CW608N | EN12163

EN12164 EN12165 EN12167 |

CuZn38Pb1,5 | |

| CuZn39Pb2 | CW612N | EN12164

EN12165 EN12167 |

CuZn39Pb2 | C 37 700 |

| CuZn39Pb3 | CW614N | EN12163

EN12164 EN12165 EN12167 |

CuZn39Pb3 | |

| CuZn40Pb2 | CW617N | EN12163

EN12164 EN12165 EN12167 |

CuZn40Pb2 | C 37 800 |